|

Volume 24.1 |

||

| Focus on Validation of Simulation | ||

| DatapointLabs' new CAETestBench™ validation service is designed to probe the accuracy and robustness of simulations against a controlled physical test utilizing carefully designed, standardized geometries. Quantitative comparisons of simulation to real life are achieved. Simulation model files, software iteration results, and the experimental test cases are delivered using Matereality’s PICSCI ELN software at https://caetestbench.picsci.com/. Clients can log in and access their data electronically, use on-line comparison modules, and also take advantage of a private workspace for continued validation iterations where they can evaluate the impact of any changes they make to their simulation parameters. Validations are now available as an optional add-on to certain TestPaks® for the following cases:

Crash/Drop Test Simulation

This validation is available for: Support for other crash codes may be available on request. Additive Manufacturing Validation for Design Optimization

This validation is available for: Non-linear Structural Simulation of Ductile Injection-Molded Plastics

This validation is available for Abaqus. Support for other codes may be available on request. Rubber Hyperelastic Model Validation

This validation is available for ANSYS. Support for other codes may be available on request. |

||

| Book Review: Simulation Verification and Validation for Managers | ||

|

This booklet is intended to be a guide to the V&V process. Starting with a carefully defined vocabulary of commonly used terms, the authors proceed to outline the right methods, resources, time commitments, and realistic expectations for V&V. It is made clear that making design decisions using simulation results without V&V represents an area of risk. A section on Risks and Trade-Offs describes why validation is needed for simulation-driven design, whether simulation-based or simulation-informed, and provides guidelines on situations where it might be reasonable to neglect the V&V process. Coupled with V&V is the notion of uncertainty quantification (UQ), a routine concept in well run test laboratories, where a process is developed to quantify the band of error associated with each aspect of a test, or simulation in this case. UQ strengthens the simulation by providing realistic bounds around the simulation result. Section 4 asks a series of important questions which allow the manager to lay out the appropriate resources for the needs of the enterprise. The uncertainties of the simulation tool itself are discussed next, along with steps that must be taken by the software developer to verify the simulation. The validation, usually performed by the simulation user, is described in a simple flow-chart. The validation step is differentiated from the Application Domain, in which a validated simulation process is now used to forecast what might occur under conditions for which there may be no direct experimental corroboration data, such as a new product or use case. Simulation Verification and Validation for Managers, by William L. Oberkampf & Martin Pilch, is available from directly from NAFEMS. |

||

|

|

||

|

strengthening the materials core of manufacturing enterprises |

|

|

DatapointLabs Technical Center for Materials | 95 Brown Road #102, Ithaca, NY 14850 USA | T: +1-607-266-0405 | US toll-free: +1-888-DATA-4-CAE | info@datapointlabs.com |

||

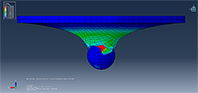

In modeling materials for use in crash applications, it is useful to determine the validity of the material model as well as its applicability over the multi-axial stress states that usually accompany these events. Conventional material models are based on rate-dependent tensile (uniaxial) stress-strain data. The validation is performed using a falling dart experiment, a high speed event with multi-axial behavior. Validation provides a measure of confidence in the ability of the simulation to model the more complex phenomena. It also provides a meaningful basis for model extrapolation and failure modeling. A technical paper related to this topic can be found at

In modeling materials for use in crash applications, it is useful to determine the validity of the material model as well as its applicability over the multi-axial stress states that usually accompany these events. Conventional material models are based on rate-dependent tensile (uniaxial) stress-strain data. The validation is performed using a falling dart experiment, a high speed event with multi-axial behavior. Validation provides a measure of confidence in the ability of the simulation to model the more complex phenomena. It also provides a meaningful basis for model extrapolation and failure modeling. A technical paper related to this topic can be found at  The combination of design optimization and additive manufacturing results in unique designs that have no prior performance history. Structural analysis provides the best way to assess design viability by reducing the number of prototypes that must be built and tested using this costly process. Validation of the structural analysis simulation prior to commercial use ensures a more viable development path with higher success rates. Validation is performed using a standardized torsional crank geometry and is available for the direct metal laser sintering (DMLS) process. Technical papers related to this topic can be found at:

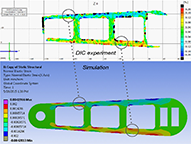

The combination of design optimization and additive manufacturing results in unique designs that have no prior performance history. Structural analysis provides the best way to assess design viability by reducing the number of prototypes that must be built and tested using this costly process. Validation of the structural analysis simulation prior to commercial use ensures a more viable development path with higher success rates. Validation is performed using a standardized torsional crank geometry and is available for the direct metal laser sintering (DMLS) process. Technical papers related to this topic can be found at:  Ductile polymers are conventionally simulated using an elasto-plastic material model which is known to have limitations, because plastics do not behave like metals. The injection-molding process can also influence the part performance. Assessing these effects on the simulation can be accomplished by validation against a standardized molded part, which is subjected to complex deformation while under observation using digital image correlation (DIC). Detailed surface strain measurement allows for the evaluation of accuracy limits of the static simulations. A technical paper related to this topic can be found at

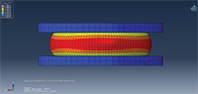

Ductile polymers are conventionally simulated using an elasto-plastic material model which is known to have limitations, because plastics do not behave like metals. The injection-molding process can also influence the part performance. Assessing these effects on the simulation can be accomplished by validation against a standardized molded part, which is subjected to complex deformation while under observation using digital image correlation (DIC). Detailed surface strain measurement allows for the evaluation of accuracy limits of the static simulations. A technical paper related to this topic can be found at  Rubbers, thermoplastic elastomers, silicones, and other highly elastic materials are often subjected to very large deformations in their applications. Simulating these behaviors correctly depends heavily on the choice of hyperelastic material model and element type. Factors such as element distortion and contact can further degrade simulation quality. The effect of these factors is hard to evaluate, because the data are non-linear and multi-dimensional. Validation is performed using a compression experiment which produces both contact fold-over and element distortion problems, allowing for a realistic check on simulation quality. A technical paper related to this topic can be found at:

Rubbers, thermoplastic elastomers, silicones, and other highly elastic materials are often subjected to very large deformations in their applications. Simulating these behaviors correctly depends heavily on the choice of hyperelastic material model and element type. Factors such as element distortion and contact can further degrade simulation quality. The effect of these factors is hard to evaluate, because the data are non-linear and multi-dimensional. Validation is performed using a compression experiment which produces both contact fold-over and element distortion problems, allowing for a realistic check on simulation quality. A technical paper related to this topic can be found at: